MOM panoramic view

Manufacturing Execution System (MES)

Warehouse Management System (WMS)

AGV Control and Scheduling System

IOT data acquisition and monitoring system

Overview of Linkeddata AGV Control and Dispatch System

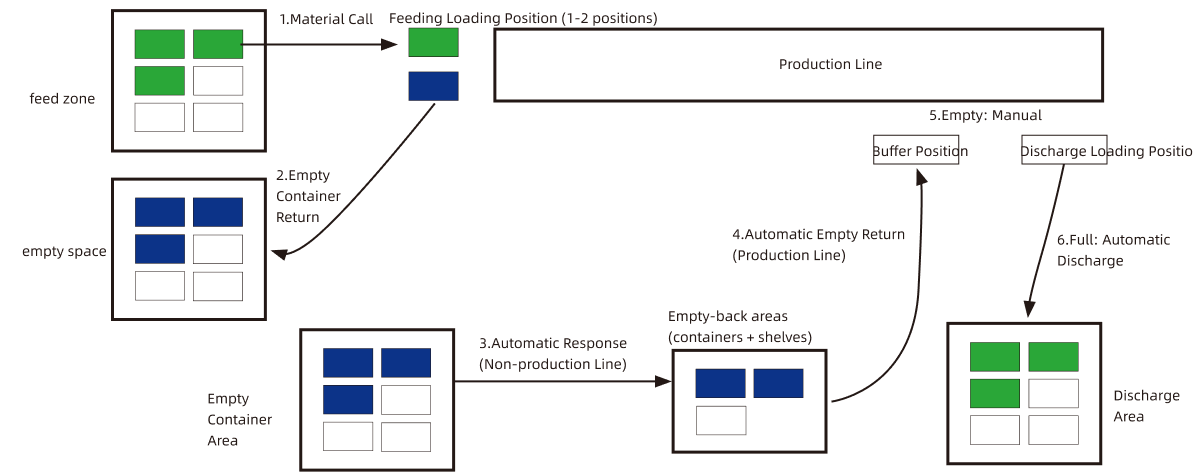

The AGV (Automated Guided Vehicle) control and dispatch system is a system that automates on-site logistics in production workshops. It mainly completes the unmanned automatic transportation function on-site through dispatching strategies and docking with the AGV execution system.

Industry Pain Points

Low Efficiency of Manual Handling On-site

Lack of advanced technology and automated equipment, relying on manual handling. Instability of demand may lead to cyclical fluctuations in handling work, making it difficult to arrange personnel reasonably.

Excessive and Disorganized On-site Materials

Materials are not effectively managed, leading to disorganized, mixed, and lost materials, affecting product production and quality.

Difficulty in Material Traceability

Lack of clear material traceability and process visualization makes it difficult to quickly locate materials required for specific work orders during production. The flow direction and usage process of materials need to be manually recorded, which poses a risk of human error and affects the accuracy of traceability.

Difficulty in Managing Turnover Containers

When the number of material containers is large, different types or batches of containers may be mixed together, making manual tracking and management very difficult.

0510-8521 1230

0510-8521 1230