Optimize Production Plans and Save Production Resources

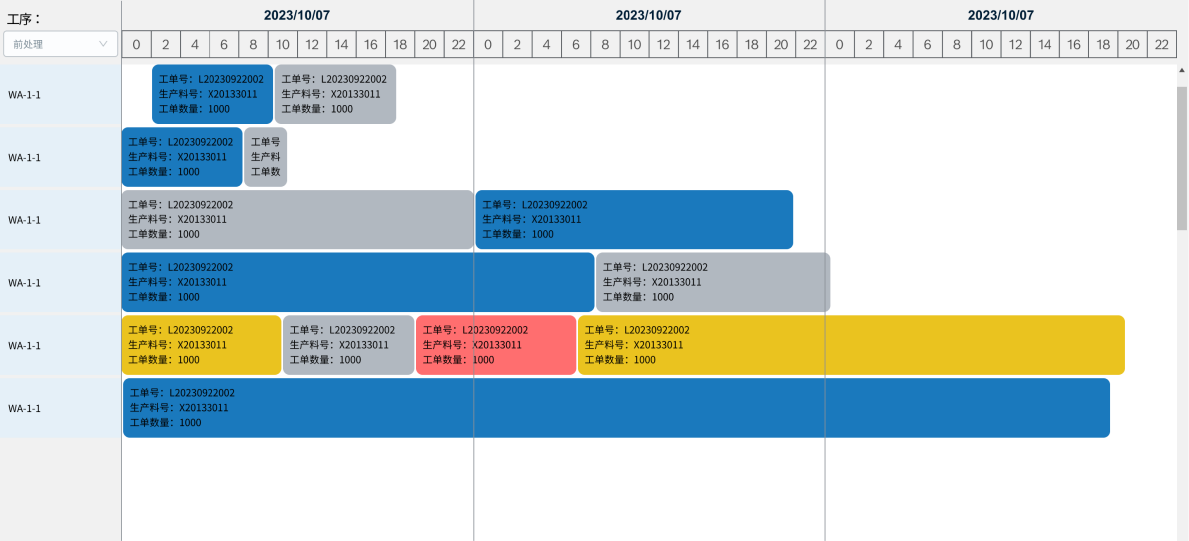

Utilize the multi-condition optimization function of Production Planning, considering multiple constraint factors such as equipment capacity, human resources, and raw material supply. By comprehensively considering multiple factors, the optimal production plan is formulated.

Shorten Production Cycle and Improve Customer Delivery

Timely updated data helps predict problems and respond quickly, thereby shortening the production cycle. Produce based on actual customer needs, avoiding overproduction and inventory backlog.

Alleviate Bottleneck Processes and Improve Capacity

Use APS to analyze bottlenecks in the production process, identifying key constraints on production efficiency.

Optimize bottlenecks to improve the overall throughput of the production line.

Improve Personnel Efficiency

Digital balance sheet of demand and supply, algorithm-driven manufacturing, improving labor efficiency.

Reduce Inventory and Lower Capital Pressure

Optimize inventory levels using Production Planning to achieve Just-In-Time (JIT) or minimal inventory levels.

Reduce inventory holding costs while ensuring timely demand fulfillment.

0510-8521 1230

0510-8521 1230