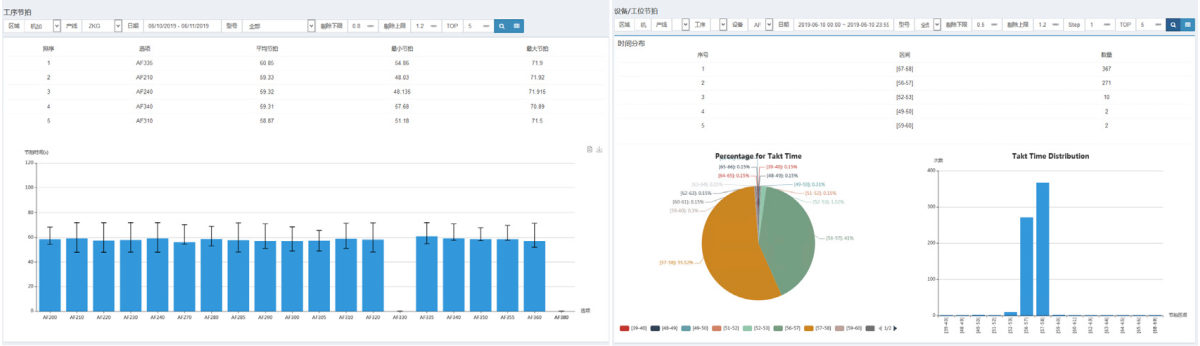

Automatic Cycle Time Statistics and Analysis for Equipment and Manual Workstations

By collecting data and calculating Cycle Times for automatic equipment and manual workstations, identify bottlenecks in these areas that lead to reduced production efficiency. Develop improvement plans based on analysis results. Optimizing problem areas can help improve overall production efficiency and reduce production cycles.

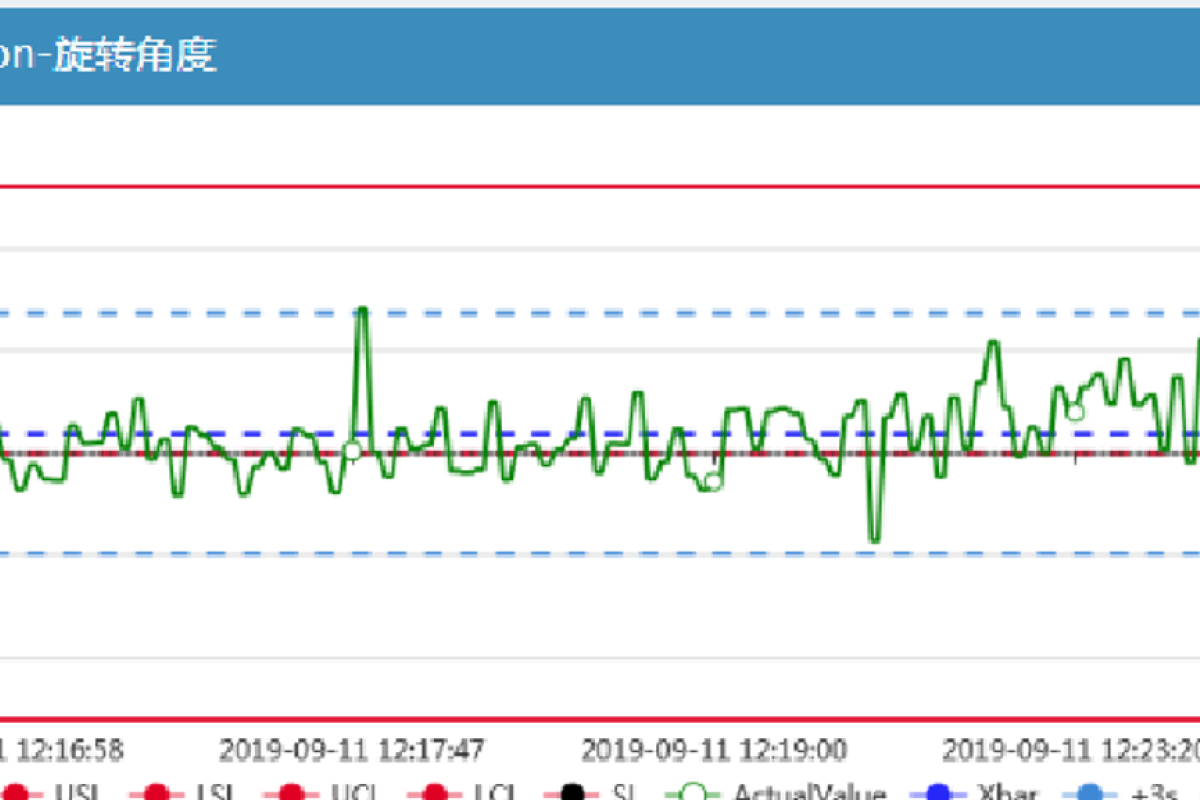

Quickly Identify Cycle Time Deviations

Set standard Cycle Times and deploy real-time monitoring systems. Use sensors, PLCs, and other devices to collect production data from automatic equipment and manual workstations for Cycle Time statistics. Utilize data visualization tools to compare actual production Cycle Times with standard Cycle Times, helping quickly identify any deviations.

Active Notification of Cycle Time Anomalies to Eliminate Deviations in Time

Set up an alarm mechanism to promptly notify relevant personnel when Cycle Time deviations are detected. Use automated analysis tools, such as data analysis software or AI systems, to quickly identify patterns, anomalies, and trends. These tools can automatically analyze large amounts of data, provide in-depth insights, and help determine which factors cause Cycle Time deviations. Develop quick and targeted improvement plans based on identified deviations.

/sysTab.png)

0510-8521 1230

0510-8521 1230