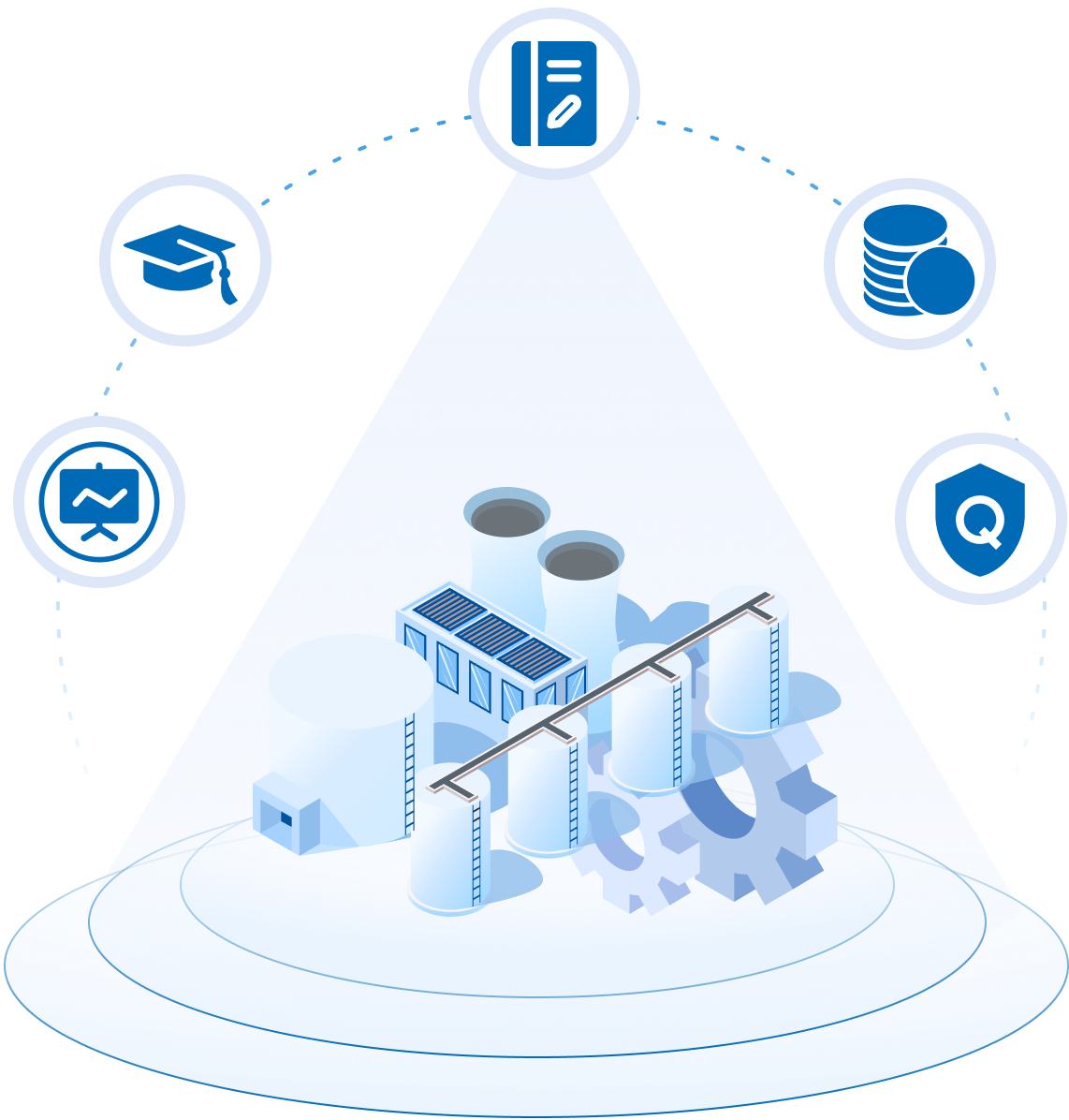

MOM panoramic view

Manufacturing Execution System (MES)

Warehouse Management System (WMS)

AGV Control and Scheduling System

IOT data acquisition and monitoring system

Overview of LinkedData MOM

LinkedData MOM (Manufacturing Operations Management System) is centered around the MES Manufacturing Execution System, integrating with customer planning, warehouse management system, advanced scheduling, quality management system, and other related systems. It covers five major manufacturing areas: planning, logistics, production, quality, and equipment. It is a software system that integrates manufacturing execution and factory operations for comprehensive digital management of factories. As the best execution platform for enterprise manufacturing processes, LinkedData MOM deeply integrates lean production and zero-defect quality concepts, providing the most suitable smart manufacturing practices for customers.

Industry Pain Points

Extensive Management, Low Efficiency

Enterprises face a gap between their management capabilities and the goal of high-quality development.

Lack of Professional Skills and Talent

With insufficient attractiveness to talent in manufacturing enterprises, there is a need to adopt innovative technologies to enhance management levels, increase talent attraction, and continuously accumulate best practices in operations management within the enterprise.

Diverse Customer Demands

Enterprises need to respond quickly, flexibly, and efficiently to customer needs. Under the agile delivery requirements of customer orders, more agile order delivery capabilities are needed to help enterprises win orders.

Cost Pressure from Excessive Competition

Continuous elimination of waste in equipment, personnel, materials, and delivery cycles is necessary to improve operational efficiency and reduce manufacturing costs.

Quality Regulations Compliance

Meeting industry and customer compliance requirements related to quality, and reducing quality costs.

0510-8521 1230

0510-8521 1230