MOM panoramic view

Manufacturing Execution System (MES)

Warehouse Management System (WMS)

AGV Control and Scheduling System

IOT data acquisition and monitoring system

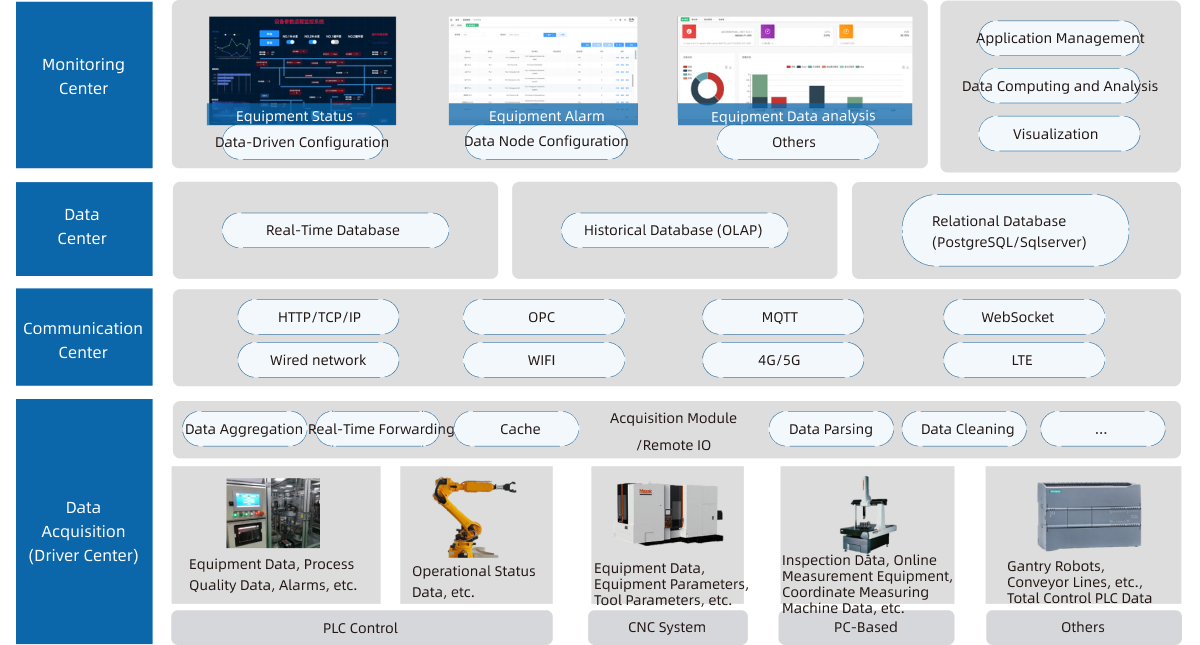

Overview of LinkedData IOT Data Collection and Monitoring System

The IOT (Internet of Things) data collection and monitoring system uses IoT technology to collect various data from production equipment, measuring devices, instruments, robots, and external sensors. It achieves real-time, impartial, efficient, and automated data collection and monitoring.

Industry Pain Points

Unclear Equipment Status

Equipment may fail, leading to downtime and production interruptions. Prolonged downtime can reduce production efficiency and increase maintenance costs.

Unbalanced Production Line

The production line may be unbalanced and have bottlenecks, leading to inefficient production processes.

Resource Waste

Energy may be wasted during production. High energy consumption increases production costs and burdens the environment.

Environmental Condition Requirements

Conditions such as temperature and humidity in the production environment can affect product quality. Inappropriate environmental conditions can lead to quality issues.

0510-8521 1230

0510-8521 1230