/sysTab.png)

設(shè)備效率改善環(huán)SMC

數(shù)字化車間管理系統(tǒng)Digital SFM

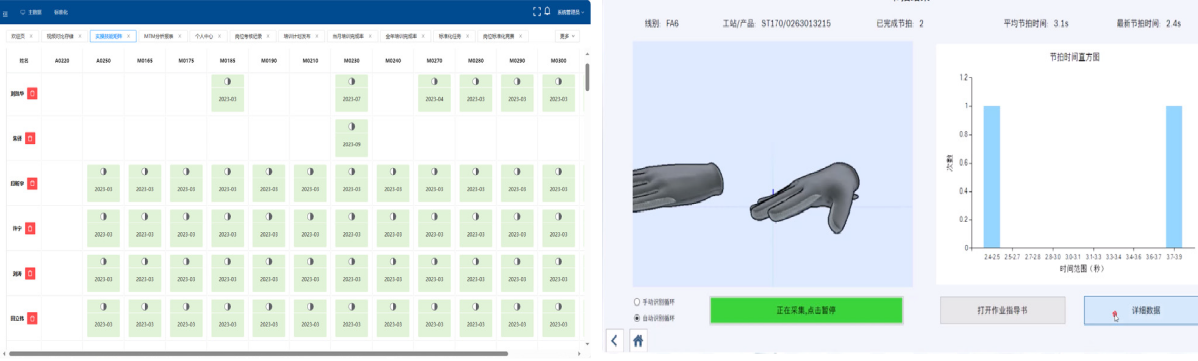

節(jié)拍分析

數(shù)字化價值流Digital VSM

智能標(biāo)準(zhǔn)化

全員生產(chǎn)維護(hù)系統(tǒng)Digital TPM

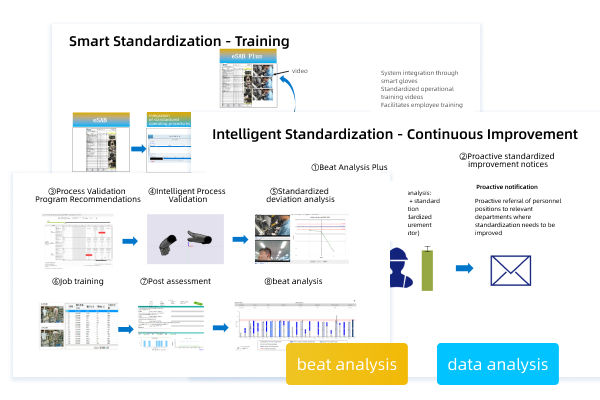

Overview of Smart Standardization

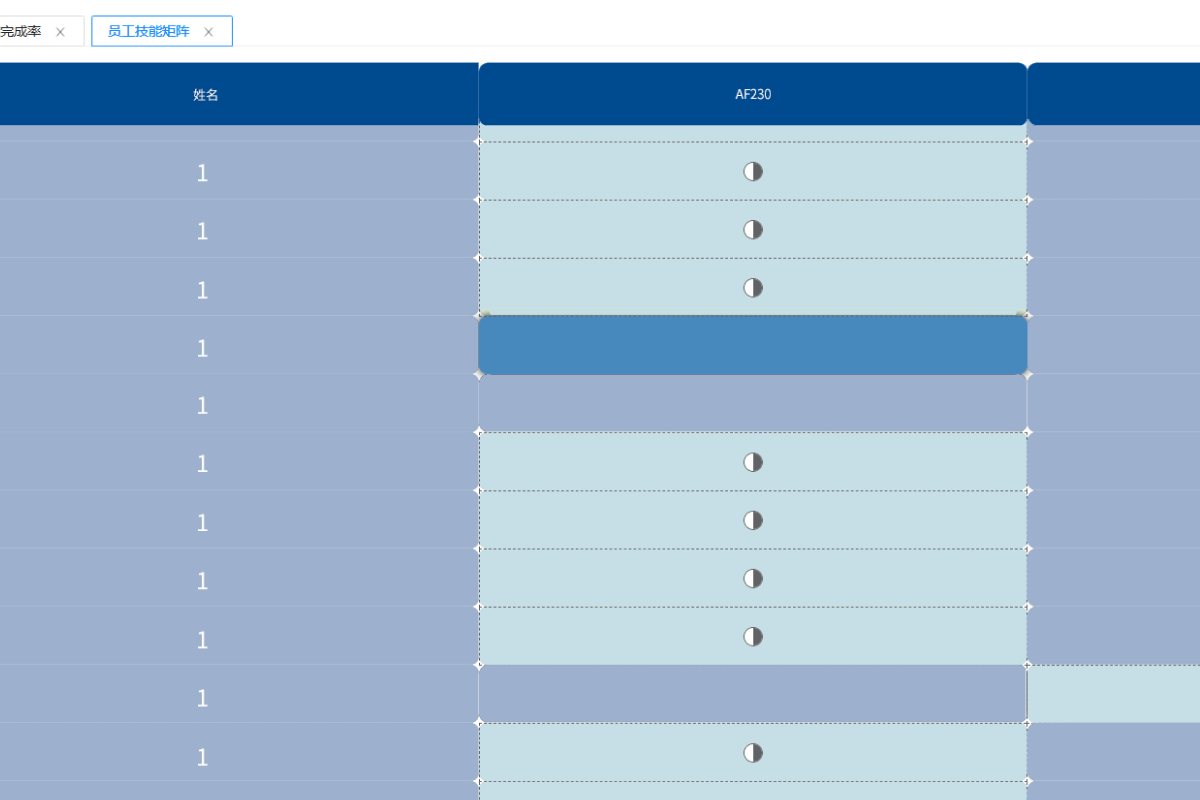

The Smart Standardization System identifies skill gaps in various positions on the production line by capturing product cycle time data from equipment and comparing the standard cycle time with the actual cycle time. By utilizing the training and examination functions in the smart standardization system and smart gloves, it improves employees' operational skills, achieving refined management of employees' operational skills, thereby increasing the standardization level of the production line.

0510-8521 1230

0510-8521 1230