Increase Production Efficiency

Through total employee involvement and preventive maintenance, increase equipment utilization, reduce

equipment failures and downtime, and improve equipment availability to maximize production efficiency.

Utilize data analysis and realtime monitoring to optimize production plans.

Provide critical production indicators to help create more reasonable production plans, avoiding

production interruptions and overproduction.

Improve Equipment Reliability

Preventive maintenance through regular inspections and maintenance reduces the probability of equipment

failures and extends equipment lifespan. Utilize sensor and IoT technology for realtime equipment

monitoring to detect potential issues and prevent equipment failures.

Reduce Costs

Preventive maintenance reduces the need for emergency repairs, lowering the expensive repair costs caused

by sudden failures.

Effective maintenance measures help extend equipment lifespan, reducing the frequency of equipment

replacement and lowering capital expenditure.

Total Employee Involvement and Team Collaboration

Promote information sharing, knowledge transfer, and collaboration among team members, strengthening team

cooperation spirit.

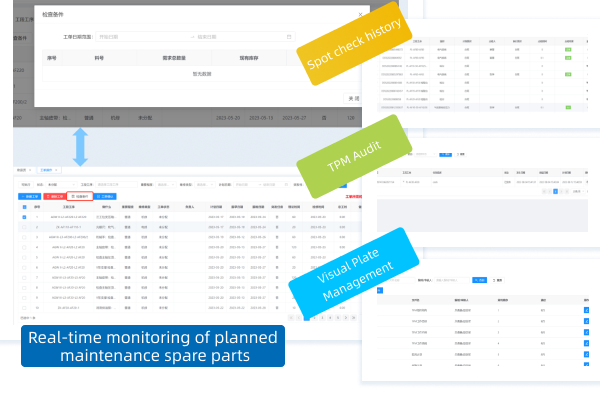

DataDriven Decision Making

Provide realtime equipment operation data and maintenance history to support management in making

datadriven decisions, effectively managing equipment and production processes.

Data analysis helps identify potential optimization opportunities, fostering a culture of continuous

improvement within the factory.

Conformity with Industry 4.0 Trends

Integrate Industry 4.0 concepts through advanced technologies such as intelligent equipment monitoring,

data analysis, and virtual training, promoting digital transformation.

/sysTab.png)

0510-8521 1230

0510-8521 1230