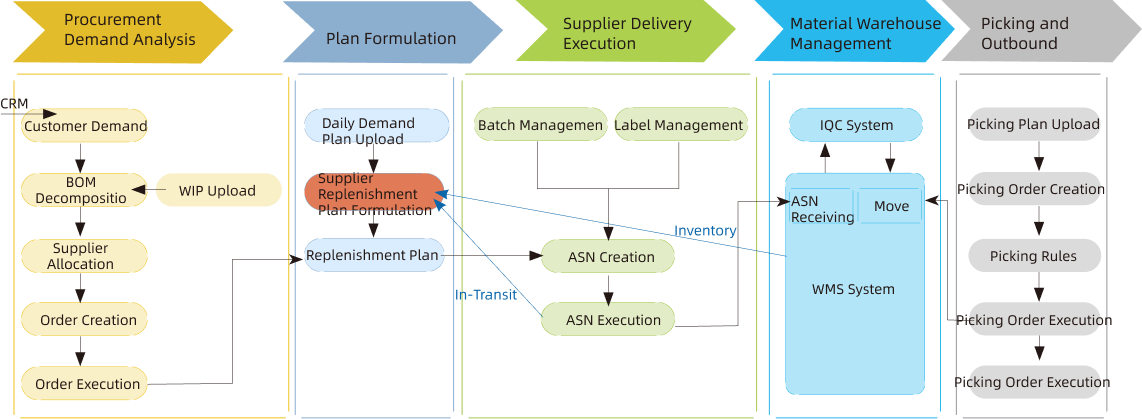

Optimize Production Plans and Save Production Resources

Establish close cooperative relationships with suppliers, sharing real-time inventory information to

ensure suppliers understand the company's inventory management strategies and agile shipping

requirements.

Adjust inventory levels based on actual demand and market changes to avoid overstock

and stagnant inventory.

Label Management for Quick Identification of Problematic Batches

Establish an effective label management system in the supply chain, defining a clear label identification

system, including key information such as product batches, production dates, and supplier

information.

By associating with label information, the system can automatically identify potentially

problematic batches.

Quantitative Supplier Performance Assessment to Improve Supply Quality

Negotiate with suppliers to establish common inventory goals, ensuring both parties have aligned

expectations for inventory levels and turnover rates.

Regularly conduct performance evaluations to

ensure the achievement of jointly set goals.

Advance Shipment Notifications to Reduce Communication Frequency and Facilitate Production

Scheduling

Share production plans and order requirements in advance to ensure suppliers are fully aware of upcoming

orders.

Negotiate with suppliers to determine a time window for advance shipment notifications,

ensuring sufficient lead time for the company to adjust production plans.

PDA Handling for Quick and Convenient Transactions

Using PDA devices avoids the cumbersome handling of paper documents. The mobility and real-time nature of

PDAs help optimize various aspects of the supply chain, improving collaboration efficiency, reducing

operational complexity, and better adapting to rapidly changing business environments.

0510-8521 1230

0510-8521 1230