/sysTab.png)

設(shè)備效率改善環(huán)SMC

數(shù)字化車(chē)間管理系統(tǒng)Digital SFM

節(jié)拍分析

數(shù)字化價(jià)值流Digital VSM

智能標(biāo)準(zhǔn)化

全員生產(chǎn)維護(hù)系統(tǒng)Digital TPM

Overview of the Shopfloor Management Cycle SMC

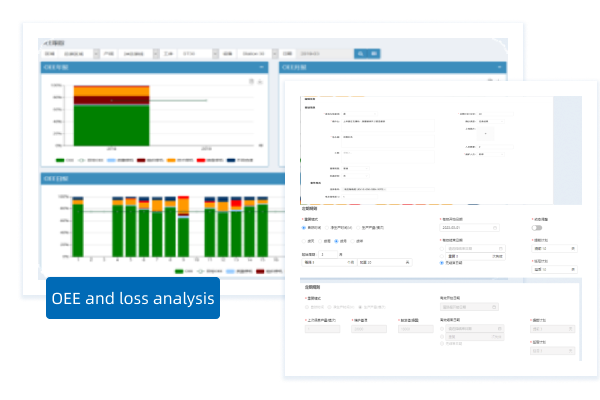

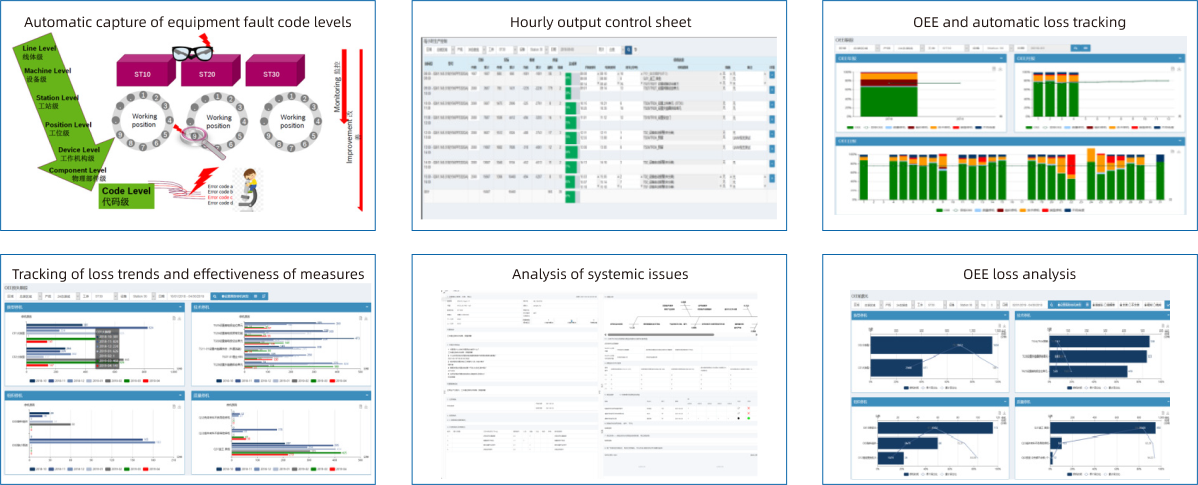

The LinkedData Shopfloor Management Cycle SMC is based on Industry 4.0 technology. It adopts advanced management models that have been proven to effectively improve equipment efficiency. By collecting equipment downtime reasons through interconnection with equipment or manual selection methods and conducting systematic statistical analysis and structured problem-solving steps, it continuously improves Overall Equipment Effectiveness (OEE), helping customers achieve operational targets.

0510-8521 1230

0510-8521 1230