/sysTab.png)

設(shè)備效率改善環(huán)SMC

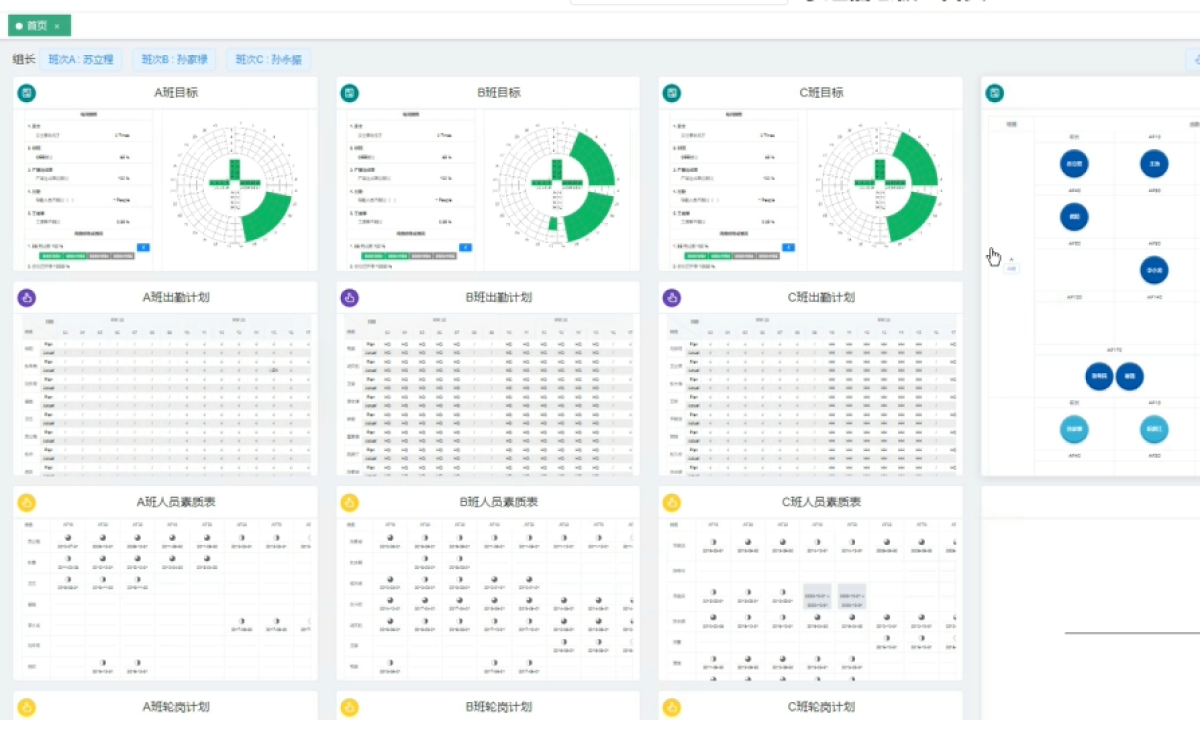

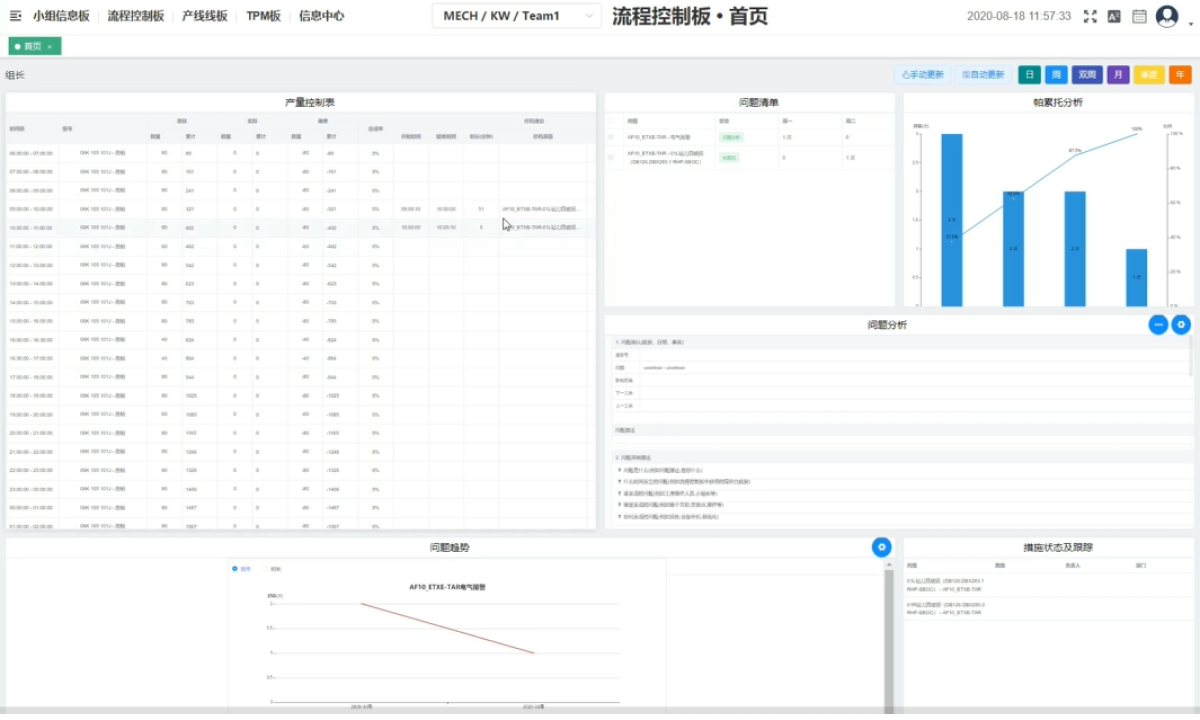

數(shù)字化車間管理系統(tǒng)Digital SFM

節(jié)拍分析

數(shù)字化價(jià)值流Digital VSM

智能標(biāo)準(zhǔn)化

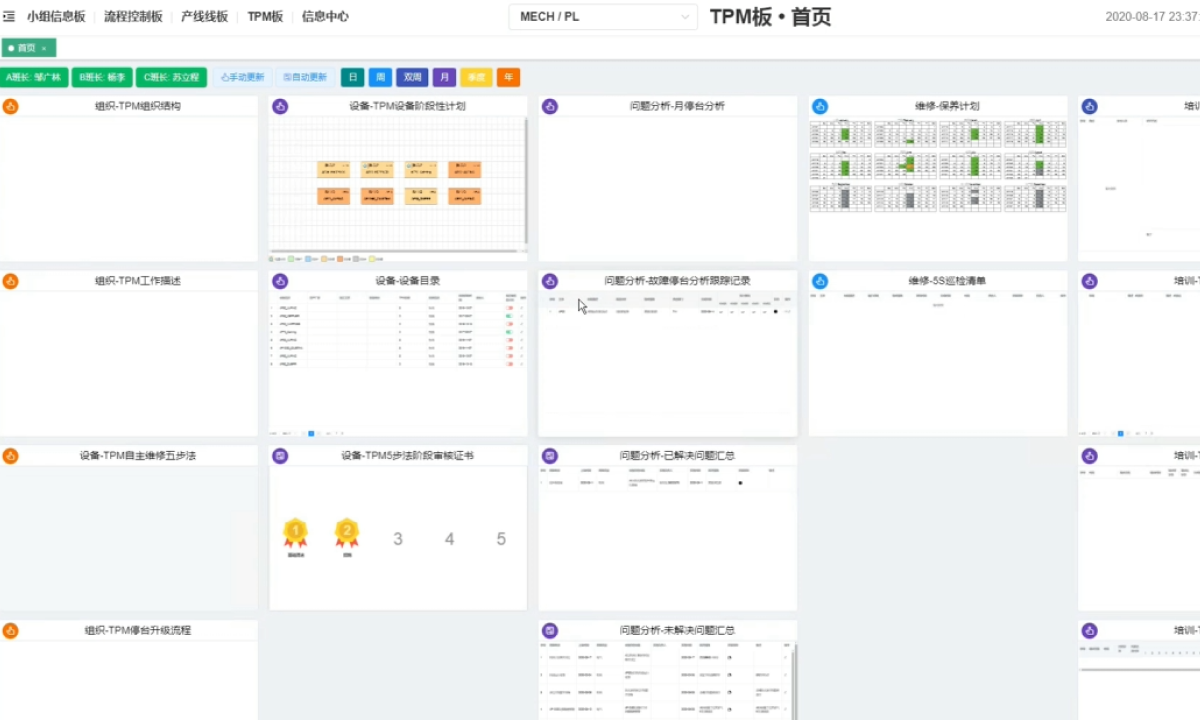

全員生產(chǎn)維護(hù)系統(tǒng)Digital TPM

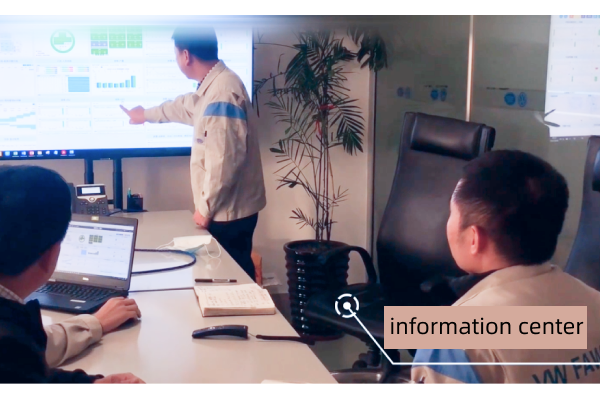

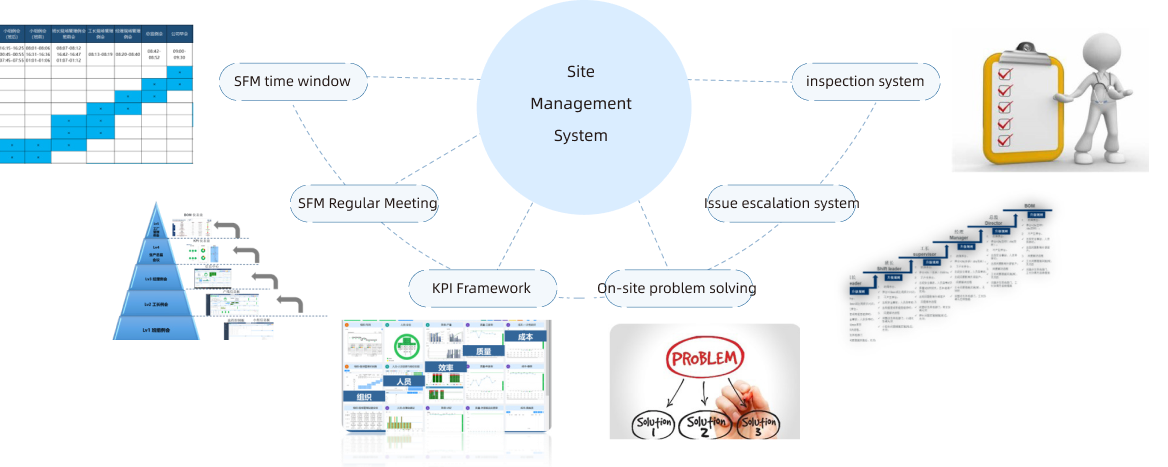

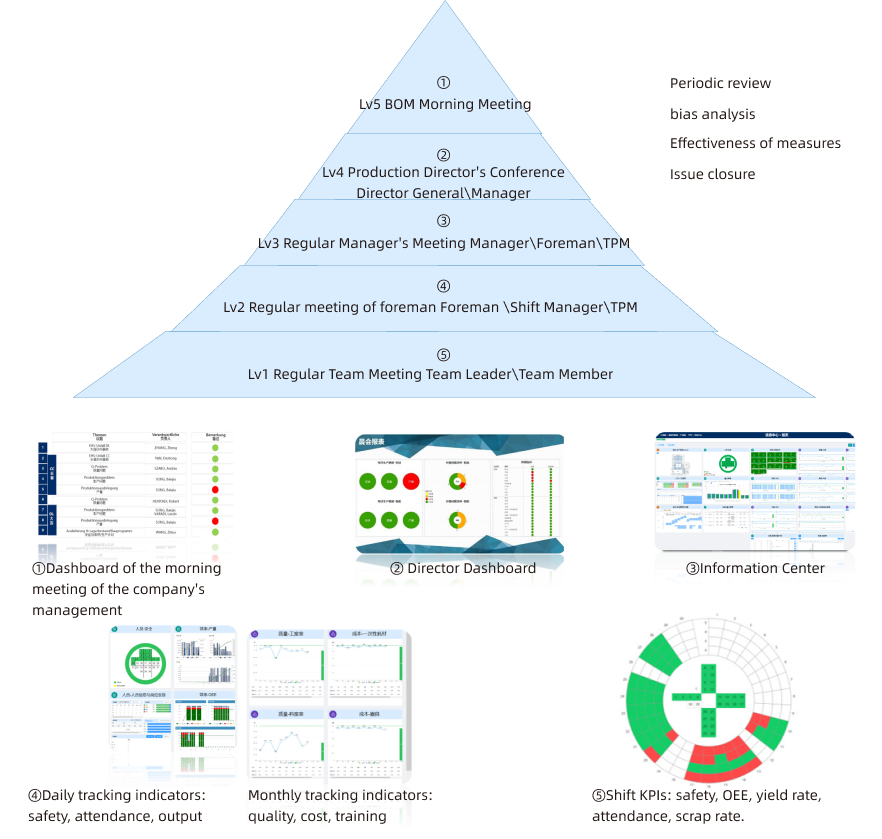

Overview of Digital Shop Floor Management System (Digital SFM)

The Digital Shop Floor Management System (Digital SFM) is an advanced shop floor management system based on Industry 4.0 technology and lean improvement concepts. It effectively combines corporate business goals with shop floor management, continuously helping companies achieve business objectives through data analysis, intelligent methods, employee capability enhancement, and continuous improvement activities.

0510-8521 1230

0510-8521 1230