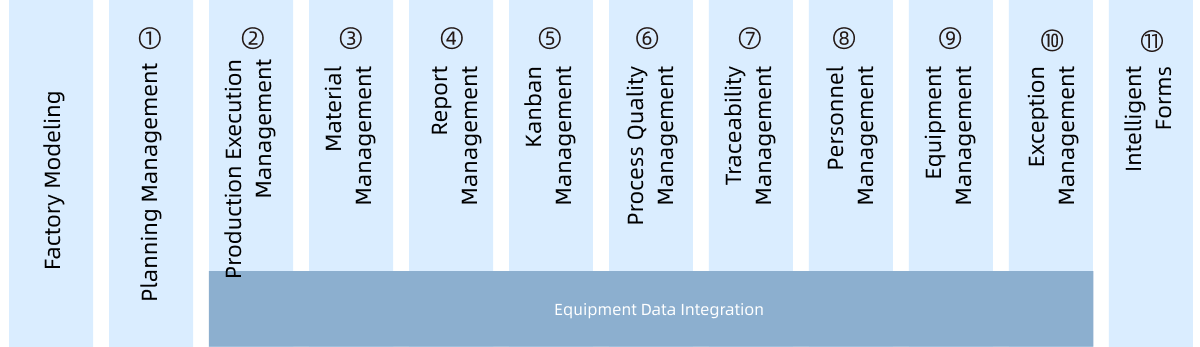

MOM panoramic view

Manufacturing Execution System (MES)

Warehouse Management System (WMS)

AGV Control and Scheduling System

IOT data acquisition and monitoring system

Overview of LinkedData MES

The MES (Manufacturing Execution System) is a production information management system for the execution layer of manufacturing enterprises. It achieves shop floor control through complete visibility of the production lifecycle and full integration with manufacturing ERP. It is an application system designed to help enterprises collect and monitor production data from order receipt, production, and process control to product completion, ensuring product quality.

Core Values of LinkedData MES

Automate tasks, reduce exceptions and errors, improve product quality, and ensure accurate decision-making through real-time production data and report analysis.

Comprehensive, Real-time Production Lifecycle Visibility: Quickly identify and address issues.

Ensure Product Consistency and Regulatory Compliance: Provide full traceability and production operation monitoring, protecting brand reputation.

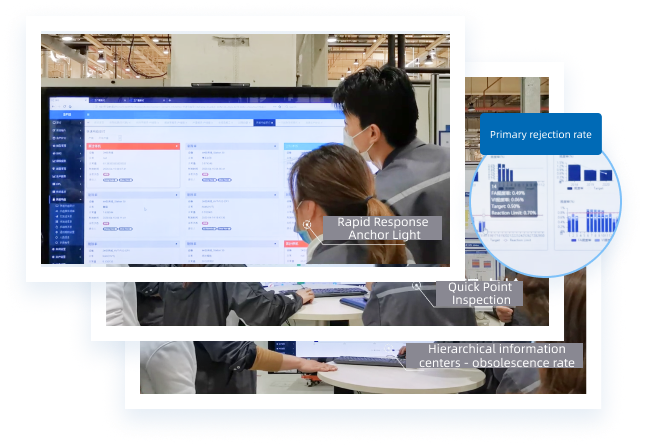

Highlights of LinkedData MES

Mistake-proofing Control

Obtain more reliable data for effective decision-making.

In many factories, shop floor information systems are the weakest link, with data collection and reporting still done manually via Word, Excel, etc. LinkedData MES offers a paperless, user-friendly operator control panel that automates tasks, prevents human errors, and improves productivity. Companies can support better decisions using real, complete, and reliable data, avoiding quality issues caused by human error.

Real-time, Transparent Shop Floor Management

Both management and shop floor can view and use the same real-time data.

The complexity of manufacturing enterprise informatization often leads to information silos among various systems. Based on LinkedData’s universal data platform, LinkedData MES achieves data sharing among various systems through single sign-on, allowing management to access the entire production lifecycle anytime, anywhere on any connected device.

Seamless Integration with ERP

Actively respond to market demands or customer changes without affecting production.

LinkedData MES is compatible with mainstream ERPs, and its open interfaces support rapid integration with ERP systems. This ensures efficient alignment of production plans and sales plans, tightly matching the production process with market demands.

0510-8521 1230

0510-8521 1230