Manufacturing enterprises are encountering unprecedented challenges during their digital transformation journey. Leveraging extensive industry experience and robust expertise, LinkedData provides end-to-end support—from top-level planning to execution—helping clients achieve business growth and operational excellence.

Are You Also Facing These Digitalization Challenges?

As manufacturing transforms and upgrades, companies often encounter the following issues during their digital journey:

A: “We spent money but saw no returns.”

B: Significant investments in production and logistics automation yield no efficiency improvements due to lack of workforce optimization.

A: “Digitalization has become just for show.”

B: Applications are limited to model lines or workshops and fail to scale, resulting in no economies of scale.

A: “Unable to match changing business demands.”

B: Automation and digital solutions require costly adjustments when business scenarios evolve.

A: “High maintenance costs.”

B: Automation and digital solutions demand significant maintenance resources after 1–2 years of implementation.

A: “Process-focused but capability-neglecting.”

B: Post-implementation results fall short of expectations, with no improvement in operational management capabilities.

A: “Short-sighted solutions.”

B: Immediate needs overshadow long-term demands, with technology eventually hindering product upgrades and demand fluctuations.

A: “Shallow business understanding, impractical planning.”

B: Idealized solutions fail to deliver the strategic outcomes envisioned.

A: “Fragmented efforts, lack of integration.”

B: Vendor solutions result in data silos without holistic, altruistic integration.

A: “Reactive strategy, lacking top-level design.”

B: Department-driven initiatives create high trial-and-error costs without systematic guidance.

A: “Implementation-focused, neglecting maintenance.”

B: Full lifecycle costs are overlooked, leading to hidden issues in planning and implementation stages.

How LinkedData Helps You Overcome Challenges

As a technology expert and strategic consulting partner for smart factory solutions, LinkedData provides comprehensive support for the digital transformation of manufacturing enterprises.

1. Strategic Planning with Deep Industry Insights:

Tailoring actionable transformation roadmaps based on industry expertise and your specific needs, ensuring alignment between strategy and execution.

2. Custom Solutions for Practical Implementation:

Offering tailored software, hardware, and process optimization solutions that deliver immediate impact and long-term growth potential.

3. End-to-End Support for Results Assurance:

A professional team provides step-by-step guidance from planning to implementation, helping you overcome every transformation hurdle.

4. Team Empowerment for Enhanced Execution:

Addressing the talent gap with specialized training and skill-building programs to cultivate a capable internal digitalization team.

5. Full Lifecycle Value Focus:

Providing long-term maintenance support to ensure digital solutions remain effective and adaptive throughout your enterprise’s growth.

LinkedData’s Digital Consulting & Training Services

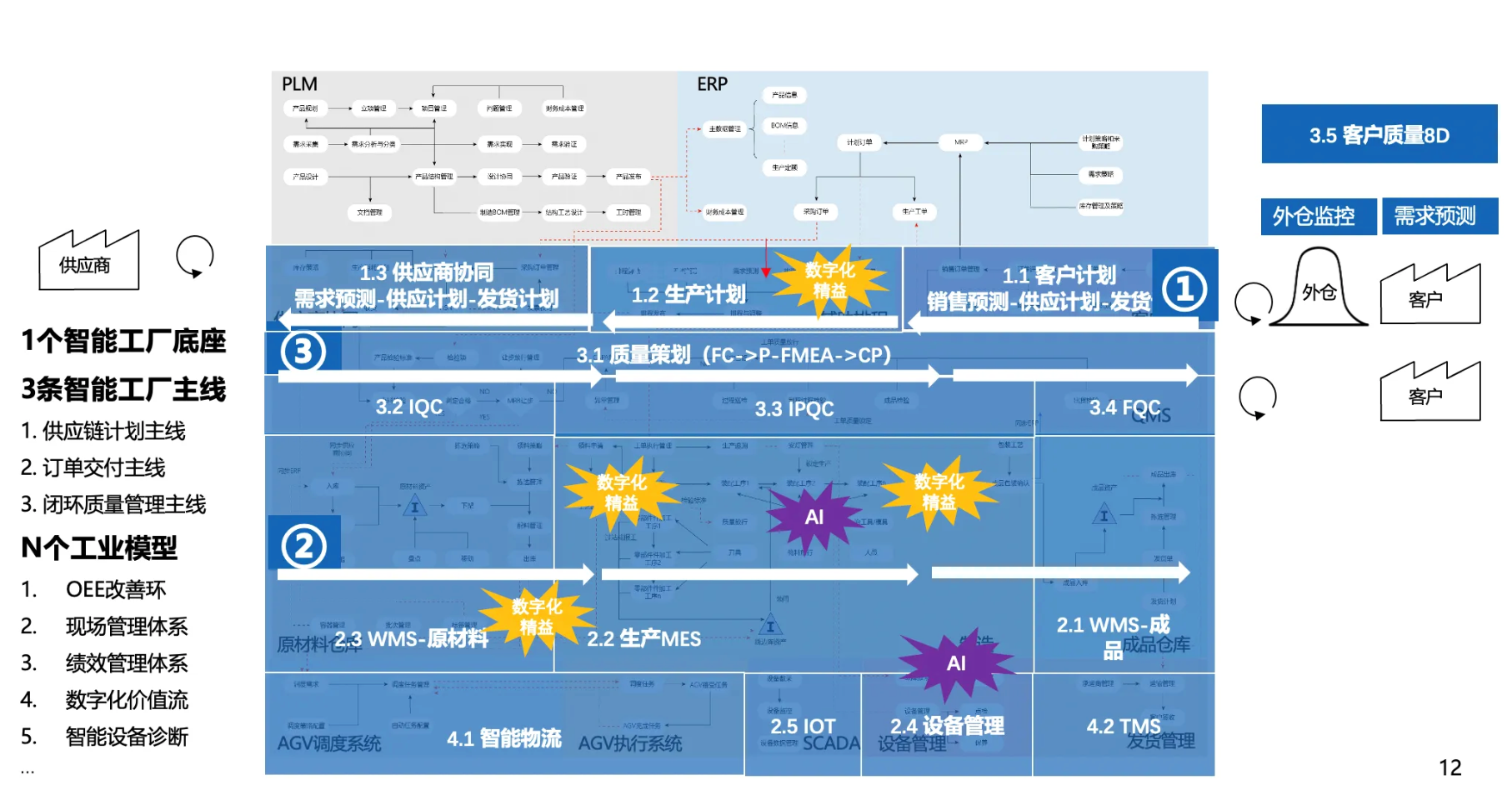

? Smart Factory Top-Level Planning:

Comprehensive review of supply chain, manufacturing, quality, and equipment processes to define optimization and digitalization strategies.

? Operational Management Consulting:

Enhancing production and management processes for operational efficiency and excellence.

? Supply Chain Management Consulting:

Improving collaboration and flexibility to quickly respond to market demands.

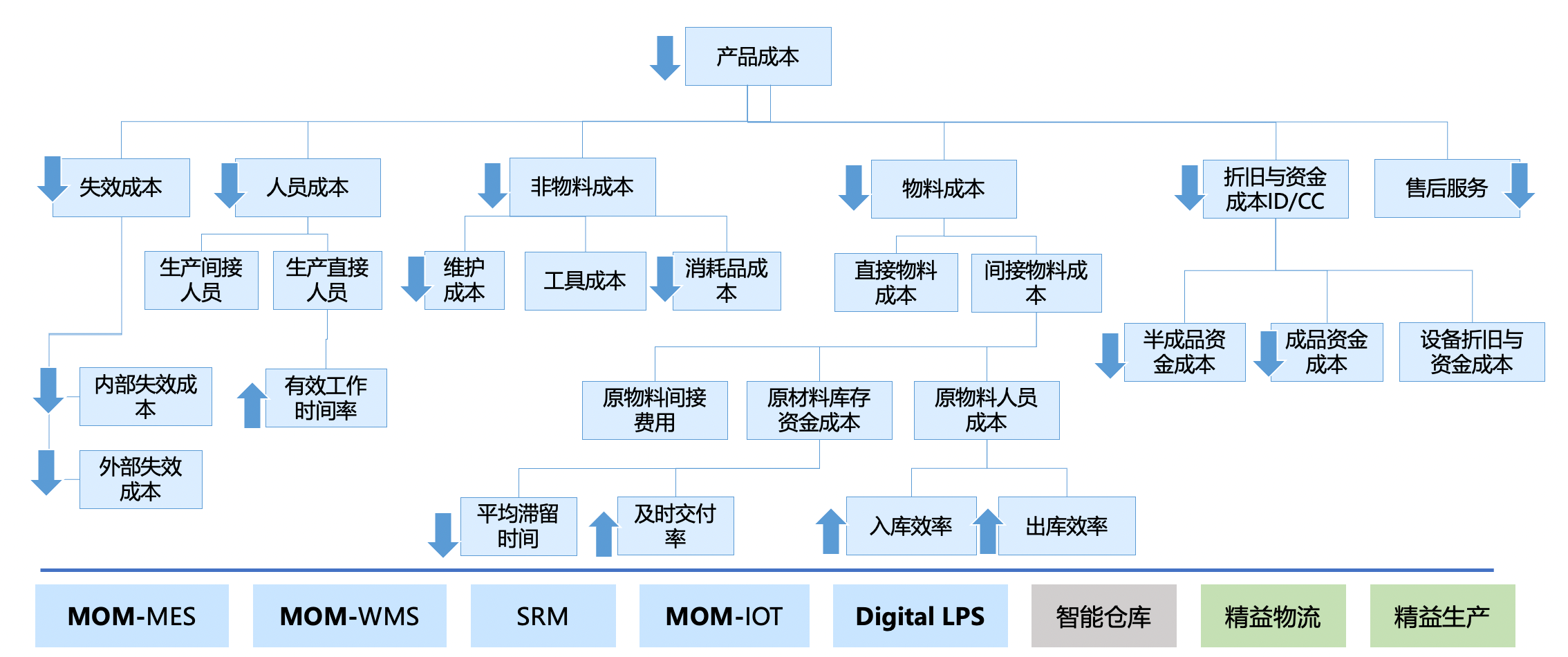

? Performance Indicator Decoding:

Systematic analysis of key performance indicators to establish a robust metrics framework for monitoring and improvement.

? Lean Management Training:

Customized lean management courses tailored to your enterprise to elevate your team’s digital management capabilities.Click the link to access the training course schedule!

LinkedData Lean Management Training Courses.xlsx

Why Choose LinkedData?

1. Expertise in Automotive Components:

With 20+ years of industry experience, LinkedData understands manufacturing pain points and transformation needs, delivering successful solutions for over 200 leading enterprises.

2. Systematic Improvement Methodology:

A holistic methodology that ensures continuous improvement across the supply chain, delivering practical and testable solutions aligned with both strategic and operational needs.

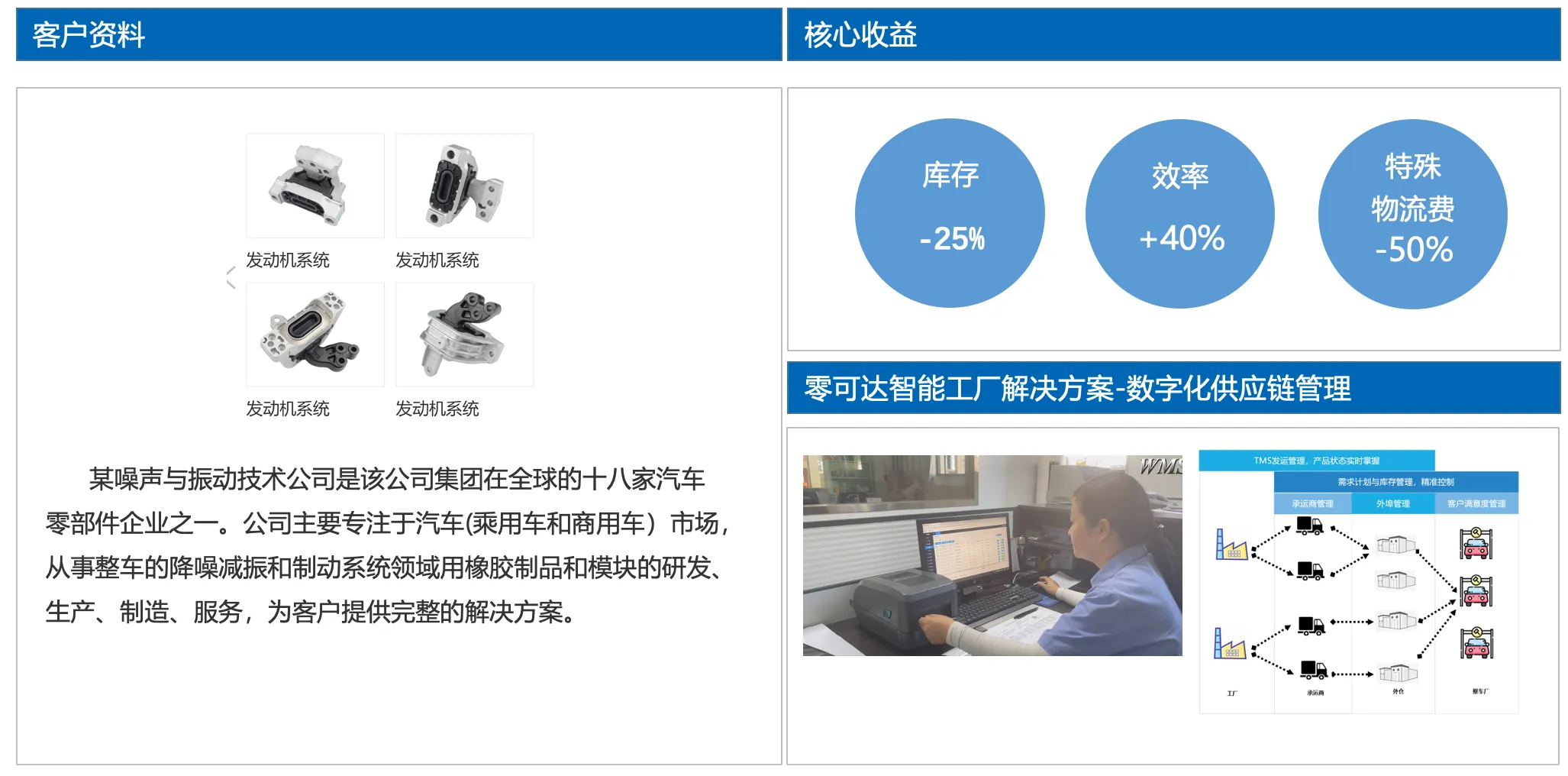

3. Proven, Quantifiable Success Cases:

Examples include efficiency gains, cost reductions, and measurable business value for clients like a powertrain company, an automotive parts factory, and a components manufacturer.

A Powertrain Company

An Automotive Parts Factory

A Components Manufacturer

4. Customizable and Flexible Solutions:

Tailored solutions for both single production line upgrades and large-scale digitalization projects, ensuring scalability and adaptability to meet current and future business needs.

5. Strong Cross-Industry Collaboration Network:

Partnering with leading global consulting firms, LinkedData integrates top-tier theoretical and practical knowledge to deliver world-class solutions.

Digital Transformation Is a Strategic Necessity

Every step of digital transformation may be fraught with challenges, but with LinkedData’s professional, meticulous, and committed approach, we aim to be your trusted partner on this journey.

If you have any questions or needs regarding digital transformation, feel free to contact us anytime!

Start Now! Improve Order Delivery Efficiency Immediately!

Contact us and explore order delivery efficiency improvement with LinkedData digital transformation experts.

Request a Demo

0510-8521 1230

0510-8521 1230