Triumph New Materials Partnering with LinkedData to Build a Benchmark Smart Factory in the New Materials Industry

LinkedData and Triumph New Materials Successfully Launch MOM Project, Co-Building a Benchmark Smart Factory in the New Materials Industry

Amid the wave of digital transformation in manufacturing, LinkedData Technology Information Co., Ltd. (hereinafter referred to as “LinkedData”) and Zhejiang Triumph New Materials Co., Ltd. (hereinafter referred to as “Triumph New Materials”) recently signed a cooperation agreement, officially launching the Manufacturing Operations Management (MOM) platform project. This strategic initiative marks the beginning of a partnership to explore the deep integration of intelligent manufacturing, jointly creating a leading transparent and smart factory in the industry.

About Triumph New Materials

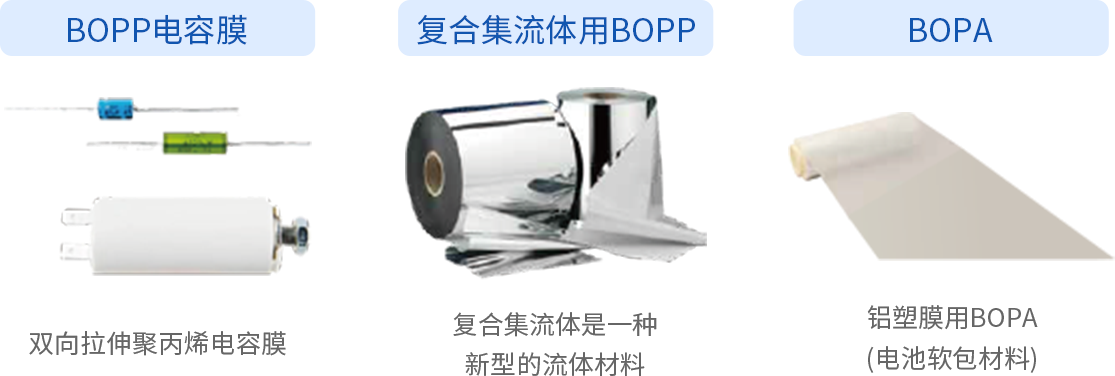

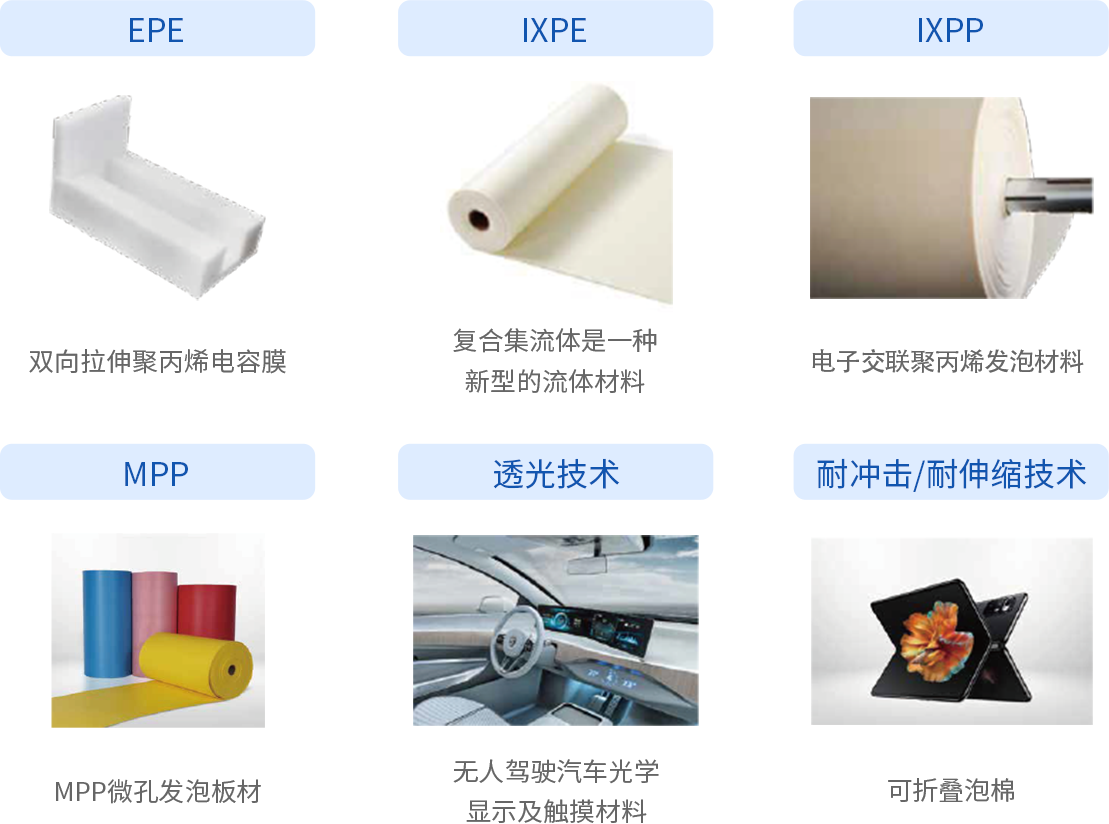

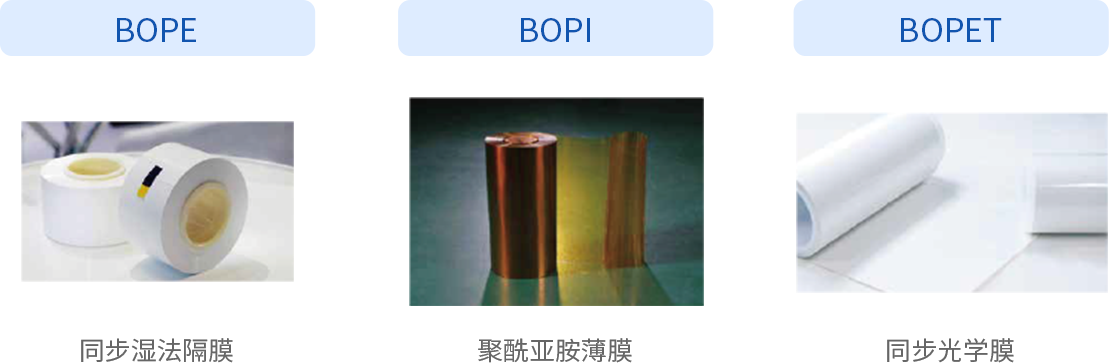

Triumph New Materials, located in Ruian, Zhejiang Province, is an ESG-driven expert in plastic new materials, focusing on research and manufacturing of innovative plastic materials. The company is dedicated to bringing surprise to human life through innovative materials and contributing to societal development. With a strong R&D team and advanced production equipment, Triumph’s main products include BOPP capacitor films, BOPA films for battery soft packs, IXPE cross-linked polyethylene foams, and more. These products are widely applied in sectors such as new energy vehicles, photovoltaics, and wind power generation, positioning Triumph as a key player driving technological advancement in the industry.

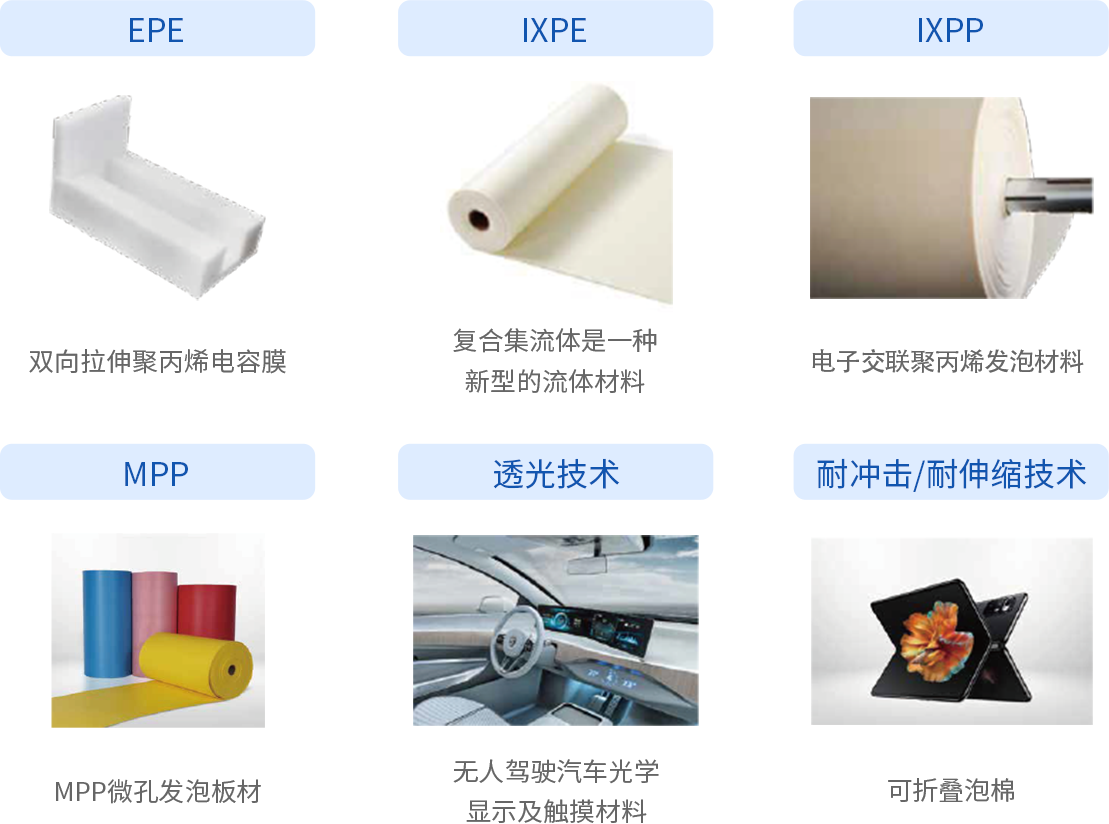

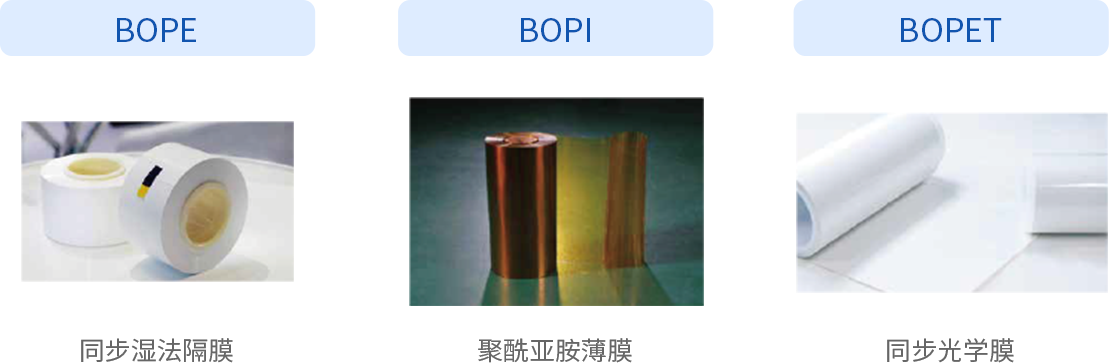

Triumph’s Products

? Film Products

? Foam Products

? Biaxially Oriented Films

Project Background

The plastic new materials industry has seen rapid growth in recent years, especially in emerging fields like new energy vehicles, photovoltaics, and wind power generation, where demand for plastic materials is steadily increasing. The strong support from governments for renewable energy and new energy vehicles has created a favorable policy environment for the development of the plastic new materials industry.

As more companies enter the field, market competition has intensified, and businesses must continuously improve their technical strength and innovation capabilities. Fluctuating raw material prices and rising production costs have created significant pressure, making cost reduction and efficiency improvement critical challenges.

Triumph New Materials is currently in a period of rapid growth. The company aims to build a systematic digital factory to achieve full-process, full-element quality traceability, positioning itself as a supplier of new materials that meet the IATF16949 quality system standard.

1. Digital Transformation of the Quality System

Triumph New Materials has recognized that the traditional human-centered quality management system can no longer meet the high standards of modern manufacturing. Through the implementation of the MOM project, Triumph will establish a new quality system that will no longer rely on individual experience but will be standardized and automated through an advanced system.

2. Building a Benchmark Factory

Triumph plans to first establish a benchmark factory in Wenzhou, Zhejiang, leveraging the MOM project to achieve intelligent and digital management. This factory will serve as a demonstration base for the company’s advanced manufacturing technologies, with plans to replicate the model at its Guangzhou factory to ensure synchronized coordination and efficient management of production processes.

3. Data-Driven Corporate Culture

The forward-thinking leader of Triumph New Materials aims to foster an open, shared, and transparent corporate culture through digital transformation. This cultural shift is expected to enhance employee innovation and responsibility, reflecting Triumph’s philosophy of “innovating technology, enriching the heart.”

4. Cost Reduction and Efficiency Improvement Goals

Facing fierce market competition, Triumph hopes to achieve at least a 20% increase in labor efficiency, reduce production costs, and enhance product quality and market competitiveness through the MOM project.

Project Implementation and Expected Outcomes

? Comprehensive Quality Management

The MOM platform will enable full-process quality monitoring from raw material warehousing to finished product shipment, ensuring precise control and continuous optimization of every step.

Modular, Scalable, and Integrated MOM Features

? Intelligent Production Scheduling

Utilizing advanced algorithms to optimize production plans, the system will ensure rational resource allocation, reduce production downtime, and increase production efficiency.

? Data-Driven Decision-Making

Real-time data analysis will provide management with decision-making support, enabling precise, data-driven decisions.

? Transparent Factory

Through digital tools, the production process will be visualized, enhancing internal management transparency and boosting employee engagement and responsibility.

The cooperation between LinkedData and Triumph New Materials represents a strong combination of professional expertise and industry experience. LinkedData has accumulated extensive technical and practical experience in the field of intelligent manufacturing, and we look forward to leveraging these strengths to provide substantial support to Triumph on its digital transformation journey.

As a leader in the new materials industry, Triumph New Materials boasts outstanding R&D capabilities and market insight. We firmly believe that with the continued advancement of the MOM project, Triumph will further enhance its smart manufacturing capabilities and solidify its leadership in the field of soft-pack batteries for new energy. By building a leading benchmark smart factory in the new materials industry, Triumph will not only achieve a 20% increase in production efficiency but also significantly enhance its market competitiveness.

0510-8521 1230

0510-8521 1230